Shougang News

First Prototype 300 MW F-class Heavy-duty Gas Turbine Independently Developed in China Rolls Off Assembly Line with Help of Beijing BEIYE Functional M

Release Time:2024-05-20 16:57:32

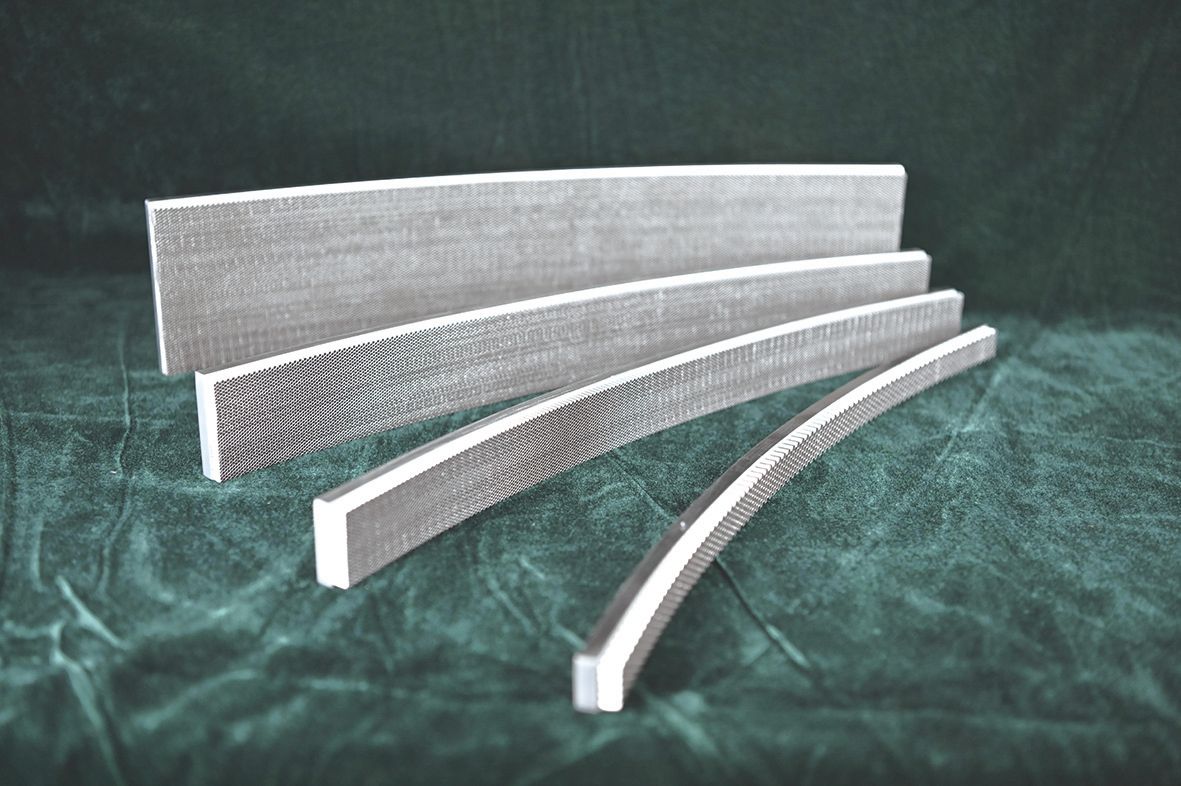

Honeycomb structural parts.

Recently, the first prototype of a 300 MW F-class heavy-duty gas turbine independently developed in China rolled off the assembly line in Lingang, Shanghai. As an important milestone in the independent innovation and development of China’s heavy-duty gas turbines, this marks that the entire manufacturing process of domestic high-power heavy-duty gas turbines has been completed based on forward design for the first time, fully entering the final stages of complete machine testing and verification. This important breakthrough in China’s self-developed advanced equipment was made possible by the wisdom and strength of the Beijing BEIYE Functional Materials Corporation.

The heavy-duty gas turbine, a core piece of equipment in the energy field, can operate for a long time in environments of high temperature, high stress and high corrosion. Widely used in ground power generation and power grid peak shaving, it has an important strategic position and broad market prospects, and is known as the “jewel in the crown” of the equipment manufacturing industry. The 300 MW F-class heavy-duty gas turbine that rolled off the production line this time consists of five major systems and more than 50,000 parts. It is China’s first self-developed heavy-duty gas turbine with the highest power and technology level, and will become an important driving force for the development of high-end equipment manufacturing. The new technologies, new materials and new processes that it adopts will have strong radiation and driving effects on progress in basic disciplines and industrial technology development, thereby ensuring China’s energy security and green development, speeding up the new industrialization and accelerating the construction of a manufacturing power.

As one of the enterprises participating in the R&D work, over the past eight years, the Beijing BEIYE Functional Materials Corporation of Shougang has faithfully and bravely taken responsibility and fulfilled its mission. It has repeatedly focused on the R&D of 300 MW F-class heavy-duty gas turbines, overcome difficulties, completed more than 20 key research projects, conquered more than 50 key technologies, obtained more than 30 invention patents, presided over and participated in a number of basic scientific research projects, and successfully developed rotor-stator master heat-resistant superalloys for castings, heat-resistant superalloy sheets for combustion chambers, cobalt-based superalloy filaments, nickel-based heat-resistant superalloy foils and other specifications of products, helping the first prototype of the 300 MW F-class heavy-duty gas turbine independently developed in China to roll off the assembly line.

It is reported that the State Power Investment Corporation is the main unit of project implementation, while the Harbin Electric Corporation, China Dongfang Electric Group Co., Ltd. and Shanghai Electric Group Company Limited established the China United Gas Turbine Technology Co., Ltd. to be responsible for the specific implementation. The first prototype was manufactured and assembled by the Shanghai Electric Group Company Limited, and more than 200 enterprises, scientific research institutes and universities in 19 provinces and cities, including Beijing, Liaoning, Shanghai and Jiangsu, participated in the R&D.

Copyright © 2003 shougang.com.cn, All Rights Reserved